manufacturing engineering

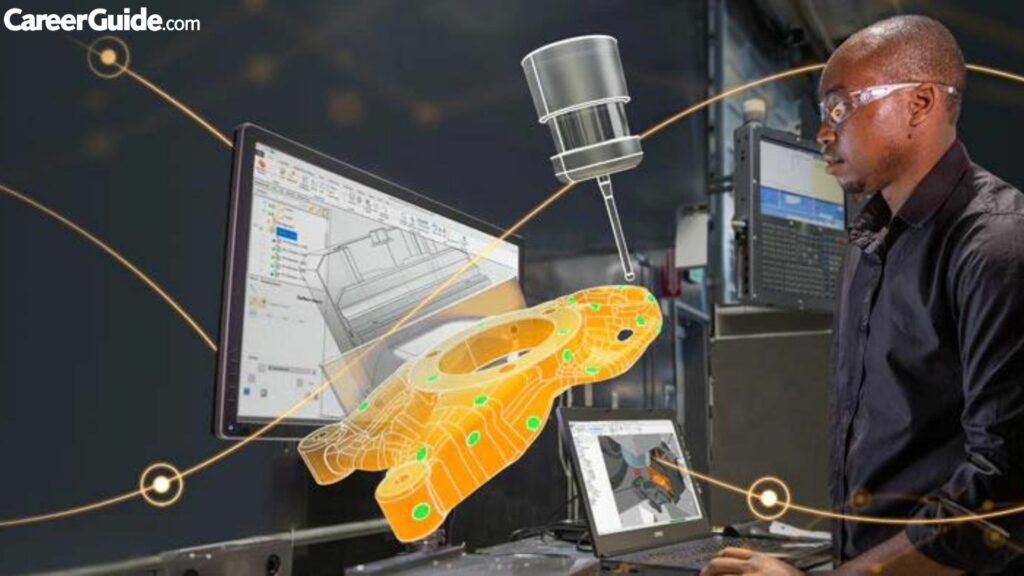

Manufacturing engineering as a career branch deals with the proceedings of giving valuable inputs by sharing designs and conceptualised concepts in different areas like mechanical, chemical, electrical, and industrial manufacturing. The aim or objective of manufacturing engineering working professionals is to in-depth research and development of over the top-quality commodities. Mechanical engineers are responsible to turn waste or raw material into a cost effective, efficient and dynamic product by toiling on it. In upcoming years, the scope of manufacturing engineering will be boosting because of its high demand in the market. Its fruition or evolution is happening itself. Manufacturing engineers’ professionals only led to the emergence of latest high-tech products and technological advancements in the discipline of science, research and development.

all about manufacturing engineering

- Manufacturing Engineering

- What Is The Role Of Manufacturing Engineering?

- How Would You Describe The Working Atmosphere For A Manufacturing Engineer?

- How Can You Turn Into A Manufacturing Engineer?

- Career Profile

- What Abilities And Traits Are Necessary To Work As A Manufacturing Engineer?

- Internship Opportunities

- Manufacturing Engineer Career Progression

ENTRANCE EXAM QUESTIONS

For instance, manufacturing engineers are the key players who created 3D/4D printing concepts, nanoelectromechanical systems, self-controlled automobiles, hyper loops and many more to serve their respective countries for bring the essence of development.

What is the role of manufacturing Engineering?

Manufacturing engineers have a variety of duties to perform. He or she is principally in charge of supervising the manufacturing processes and activities. The position entails raising manufacturing productivity. An engineer who works in manufacturing evaluates and plans workflow, space needs, and equipment arrangement. He or she is a crucial member of the group responsible for planning, setting up, supervising, and developing manufacturing machinery and assembly lines in factories or production facilities. Integrating the entire production process is the responsibility of a manufacturing engineer. He or she strives to provide the most high-quality items possible while cutting costs as quickly as possible.

download Universities/colleges cutoff

Designing

Equipment installation and design require the expertise of a manufacturing engineer. He or she tests efficient manual and automated systems in addition to creating new items. Applying practical product design expertise is a key component of the job of a manufacturing engineer.

Evaluating

A Manufacturing Engineer’s job involves assessing the current manufacturing workflows and processes to determine where improvements might be made. He or she sets up a productive and successful workflow.

NIRF top engineering colleges 2023

Observing safety regulations

Ensuring adherence to the rules of environmental protection and safety is part of the job of a manufacturing engineer. He or she uses modern technology to update systems and procedures.

Collaboration

Collaboration with other experts, including engineers, contractors, and suppliers, is necessary for a manufacturing engineer. He or she must make sure that attendees are present at brainstorming sessions and interdepartmental gatherings.

Budgeting

A manufacturing engineer must identify ways to increase productivity while lowering costs and improving quality. To satisfy performance quotas and financial objectives, he or she is in charge of developing systems and procedures.

ENTRANCE EXAM QUESTIONS

How would you describe the working atmosphere for a manufacturing engineer?

Manufacturing engineers typically operate in an office or a production environment, such as a factory, an oil/gas production facility, or a manufacturing plant. They are responsible for creating the systems that enable production. The majority of the time that manufacturing engineers are employed is spent looking up design layouts and maintaining these systems. They are in charge of making sure safety procedures are followed.

Travel is necessary for a Manufacturing Engineer?

Likely

A manufacturing engineer works on a production line or in a factory. The amount of travel is dependent on the organizations hiring. There may be a need for several Manufacturing Engineers to travel frequently.

download Universities/colleges cutoff

Work Schedules: Full-Time, Part-Time, and Remote

In most cases, a manufacturing engineer works full-time. His or her working hours range from early in the morning to late at night. In this vocation, there are no on-call, work from home, or hourly employment shifts.

Contractual, Permanent Employment

Both contract and permanent employment prospects are found by a manufacturing engineer. Through employment portals like LinkedIn, Indeed, Naukri.com, and Monster, one can locate a variety of Manufacturing Engineer career possibilities that suit their needs.

NIRF top engineering colleges 2023

Office buildings, manufacturing facilities, and factories

A manufacturing engineer works in a workplace like a factory, office, or production facility.

Geographical Area Presence

Urban, semi-urban

Employment prospects for Manufacturing Engineers are booming in urban regions. Numerous Manufacturing Engineering opportunities are available in cities like Pune, Chennai, Bengaluru, and Hosur. Manufacturing engineers who work in Bengaluru earn salaries that are 48% higher than the national average.

Time constraint Probably

A Manufacturing Engineer must guarantee work completion within the allotted time. He or she works under time pressure

ENTRANCE EXAM QUESTIONS

Longer Details

People who work as manufacturing engineers may have to put in extra time for emergencies or unique projects.

Weekly Work Hours Minimum 40 Hours

At least 40 hours are put in by a manufacturing engineer each week. His or her working hours might occasionally increase.

download Universities/colleges cutoff

How can you turn into a manufacturing engineer?

- 10+2 completion Candidates must get at least 50% of the requisite marks in physics, chemistry, mathematics, and computer science in their 10+2 from an accredited board in order to pursue a career as a manufacturing engineer.

- Entrance test Aspirants may take entrance exams held by colleges, universities, state and national level examination conducting authorities after taking the 10+2 exams.

- Bachelor Manufacturing engineering candidates may enrol in undergraduate programmes after passing their 10+2 exams. The most sought-after degrees for Manufacturing Engineers are B.Tech. or B.E.

- After Bachelor A candidate with a degree in manufacturing engineering has a wide range of employment opportunities available to them.

- Option 1: After finishing their undergraduate Manufacturing Engineer programme, candidates can enroll in a postgraduate Manufacturing Engineer programme. After finishing their academic training, individuals may begin working in the sector in an entry-level capacity.

- Option 2: They may start working in the industry in an entry-level job after successfully completing the undergraduate Manufacturing Engineer degree. After gaining a few years of work experience, students could enroll themselves in a postgraduate Manufacturing Engineer degree. The M.Tech. is the preferred postgraduate degree for Manufacturing Engineers.

NIRF top engineering colleges 2023

Career Profile

Manufacturing engineering career is the broader field and diversified in India. It has deepened its roots in numerous countries and its rising demand and professional activities achieved massive popularity in the current scenario.

- Interpreting the mechanical and thermal apparatuses, extracting out the glitch or problem and then to resolve it by implementing valid solutions.

- Relying on computer designs for attaining comprehensive overview.

- Innovating a testing model.

- Examining the outcomes of tests and incorporating changes accordingly.

- Creating and enhancing skills to build effective communication to reduce the chances of misconceptions.

ENTRANCE EXAM QUESTIONS

The monthly salary of mechanical engineering is totally based on the position or the job profile for which you have applied. The minimum monthly salary for freshers may vary from Rs. 20,000 to Rs. 40,000 which can reach up to the optimum level of the 2-3 lakhs monthly when you gain more expertise.

download Universities/colleges cutoff

Design And Operation Scope Of Work

A manufacturing engineering scope of work entirely focuses on the design and operation of the integral parts of the products or systems. Systems like computer networks, robots, machine tools, material supporting devices are dependable for the development of highly standardized and cost-effective competitive commodities.

Emerging New Technologies And Enhancements Scope Of Work

As a intrigued part of their occupation, manufacturing engineering working professionals must always maintain a constant pace with the technological fruition in the discipline to ensure that they will offer their customers with the excellent innovative advanced products.

NIRF top engineering colleges 2023

Steps To Become Manufacturer Engineers

To become an exceptionally experienced manufacturing engineer in the discipline you must have to fulfil several necessities in order to pursue it as a main profession. You have to attain a Bachelor’s degree in manufacturing engineering which is usually essential.

It is normally witnessed that several mechanical engineers at the beginning try to become manufacturing engineers which is not the case. Most of the manufacturing engineers have said that beginning from other specialised disciplines such as production engineering can be beneficial in offering supplementary educational expertise for futuristic prospects in manufacturing industries.

ENTRANCE EXAM QUESTIONS

What abilities and traits are necessary to work as a manufacturing engineer?

There are some quintessential handful of attributes or capacities, if gained good command on it then this field can be the best profession for you. Further you will also become a perfect asset for the firm on which firm can rely. This will also increase your value in the film. These abilities are essential for continuing to function well at work.

- Problem-solving abilities: A manufacturing engineer needs to be able to fix issues that arise during a manufacturing process and cause delays. He or she must evaluate the advantages and disadvantages of the substitute solution.

- Strong communication skills are necessary for a Manufacturing Engineer’s employment in order to work with other professionals, interact with team members, and explain processes, among other things. In order to keep track of actions, he or she must also document them.

- Organizing abilities are necessary for the job of a manufacturing engineer. By planning operations, imparting training, and supervising the work of other employees in the organisation, he or she is expected to plan initiatives.

- Technical Knowledge: A Manufacturing Engineer needs to be proficient in using a variety of tools, machinery, and technology. He or she must be able to handle and use a variety of tools and equipment.

download Universities/colleges cutoff

Internship Opportunities

Yes

Before beginning full-time employment, candidates who wish to pursue a career as a manufacturing engineer must choose an internship. To be eligible for internships, students must be enrolled in or have already graduated from a Manufacturing Engineering or closely related school. An internship in manufacturing engineering is essential to comprehend the complexities of the sector and how it operates. Studying performance loss is one of the interns’ many duties. Additionally, he or she names one or more crucial initiatives to help them meet their performance goals. The intern in Manufacturing Engineering’s job involves developing strategies for handling technical problems. Tools for production management tool implementation and maintenance were systematized.

Manufacturing Engineer Career Progression

Candidates who want to work as manufacturing engineers must launch their careers by earning the necessary academic credentials. Additionally, they must select a Manufacturing Engineering internship. The likelihood of landing a permanent job increases with a Manufacturing Engineering internship. An individual moves up to a senior-level Manufacturing Engineer position after gaining expertise in the field.

NIRF top engineering colleges 2023

- Junior Manufacturing Engineer: To design, construct, and ship a variety of products, a junior manufacturing engineer continues to be active in research and development. He or she chooses how to use machinery and equipment most effectively.

- Senior Manufacturing Engineer: An expert tasked with putting together the line workers and maximizing productivity is known as a senior manufacturing engineer. He or she chooses the proper equipment for the job. An experienced manufacturing engineer instructs staff members on the use of both new and old technology.

ENTRANCE EXAM QUESTIONS

What is the future of the Manufacturing Engineer profession?

With the advent of Machine Learning and Artificial Intelligence, the field of Manufacturing Engineers is continually changing. In order to increase industrial productivity, it entails collecting more data for the production operations. Distributed manufacturing, which involves assembling finished goods as they approach their final destination, is another well-liked innovation. With its assistance, businesses can lower the price of shipping goods and improve customer responsiveness.

read also:

Top Engineering Colleges in India

Download E-Book

Confused? Take Engineering Branch Selector Test

Engineering Branch Selector Test Has :

Top Searches

Tags

- Career counseling, career counselling, career counselling for students, career guidance, career opportunities, counselling for students, Engineering, Engineering Colleges, Engineering Colleges in India, Engineering Courses, Engineering Entrance Exams, engineering exam, engineering job, Manufacturing Engineering, Manufacturing Engineering as a Career Option, Manufacturing Engineering Career, Manufacturing Engineering Industries as a Career, Manufacturing Engineering Industries as a Career Option, Manufacturing Engineering Industries Career Option, Manufacturing EngineeringManufacturing Engineering Industries as a Career Option Option